I have an FPGA, actually several and massive CAM as well as CPUs and I can do ARM perhaps. I will see how the logic goes. The goal is to create the control for the first Gravity Guild station between the Earth and moon. There is no problem with shielding and there will be no thermal problems due to the enclosure. So I can use commercial chips inside the shielded control area. It would serve to establish a high speed data link between the Earth and moon as well as provide for the transfer of tons of materials. I would guess mining, construction , food, electronics, robots, and relay equipment. The actual use on the moon is not my personal concern.

The Gravity control would require some real time control of process that would be fairly critical in operation under load , but would be completely stable in its resting state without control. It is only during the transfer of energy and mass that it would require adjustment for balancing the energy transfer.

So I start with VHDL hardware description using Freehdl as a start. Xilinx and others have software available and perhaps I will avail myself of that after I get my feet wet and see the scope of the problem.

I have done CAD with many packages and even by hand or paper and taped designs, but really with all the pick and place, CNC and automated flow soldering as well as machine gun reels of parts it is just easier to use the whole tool chain (EDA) [ Electronic Design Automation ] and have it stuffed if that is necessary.

The first thing that I found strange is that "gvhdl" creates C++ code for the simulation of the logic. I have used a CAM box to simulate hardware in the past and have even designed flexible quick load ram based simulators that act like any number of parallel gates connected in any manner. The equivalent gate delay is dependent on the complexity of design and can't be used in the same way as an FPGA.

I will do a simple I2C design that I can test with a tuner or other device, probably a serial EEprom. I suppose I will perform the serial to parallel conversion of data using the protocol and then present it as 8 bits parallel with some kind of read handshake timing and a hex display that clocks at something in the human time frame. It also allows me to create an I2C test setup.

The reason I am doing it this way is because it has to be "gospel" hardware and there can be no glitches, no unexpected consequence, fail safe, and be easily transfered instantly to a spare control setup. In other words it must be absolutely bullet proof and secure from being hacked by any external event or able to compensate for something as odd as a meteorite crossing the path of materials or even sabotage. I have made many different process control systems that functioned without any down time in as long as 20 years. That was pretty good considering the kind of hardware I was forced to design with. Those designs controlled dangerous process and had to be solid or place people and product at risk. With good hardware and good design a stable and safe product can be made.

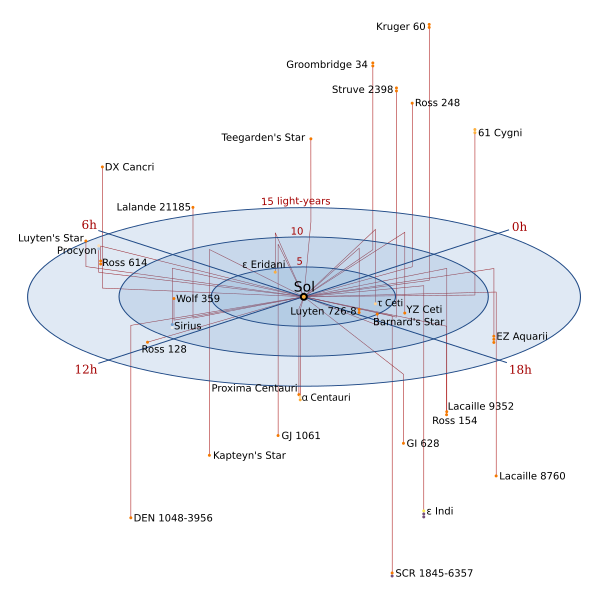

I will follow on with each step of the process to describe what I learn about EDA, and how I intend to keep the design environment in space as well. I REALLY don't want any closed source on my machines outside Earth and I want a convenient way to revise and extend the control to scale to other planets and eventually a star.

There are other considerations, but I have roughed out methods and will fill those in as I go so I can take advantage of any new discoveries along the way. I know how designs go however and I will guess it will take a week, which is 4 years of design hell. I have a few tricks up my sleeve and one can never depend on them working, but it is nice when they do.

0 comments:

Post a Comment